Menu

Menu

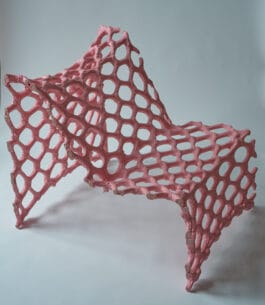

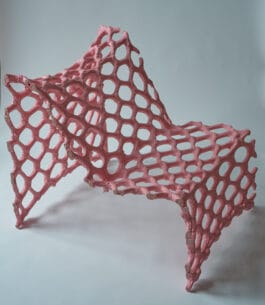

Design: S Mate Olah

Production: Norbert Schmid – Drumparam & S Mate Olah

Material: Hempstone® sprayed on hemp ropes.

Between two plywood boards, a hemp net was suspended and multiple layers of Hempstone were sprayed onto its surface.

The net structure was chosen because it doesn’t have any sharp corners that could make the material crack while shrinking. It allows the material to cover the ropes all around so the material stays on the surface and shrinks more evenly.

The flexible net structure gives room for deformation showing the immense forces of the material while shrinking, allowing deformation and resulting in a dynamic appearance.

Hemp is a versatile ingredient for biomaterials and a fast-growing plant that is considered a CO2 sink due to its CO2 binding properties.

It contains one of the strongest natural fibres and can be used for manufacturing textile, cellulose plastics, paper, composites, cosmetics, food, medication, and more.

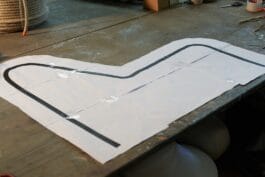

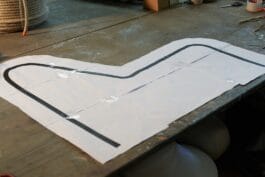

Template of the Hemp Chair. The silhouette is inspired by Armchair 42 by Alvar Aalto.

Building the framework for the hemp net structure

Hemp rope net in the making

Drilling holes along the silhouette of the chair.

ready to be sprayed with Hempstone, a mixture of water and finely grinded natural hemp fibers. (no epoxy or any other binders needed)

Small metal rods are used to reinforce the structure and make it more resistant to the strong forces of shrinking hemp composite.

Hempstone is sprayed from all possible directions onto the net structure by Norbert Schmid.

wet Hempstone surface

Hemp Chair after it is sprayed with Hempstone.

Smoothing and compressing the surface of the sprayed composite.

Smoothed Hempstone surface

Drying

Hemp Chair – varnished to make it waterproof

The chair was shaped by the shrinkage force of Hempstone.

This is especially visible around the top and bottom edge when compared to the original unsprayed net structure.

Hempstone is a biocomposite material that doesn’t require any binders and consists of water and hemp fibres.

The secret behind this material is the way it is processed: By grinding the hemp to a fine degree the surface area of the fibers are increased and when water is added intermolecular hydrogen bonds are formed between them.

This is the same reason why paper fibres stick together but the main difference is the strength of the bonds between the fibres.

The hemp is mixed with water in a 1 to 10 ratio and sprayed in multiple layers and dyed with mineral pigments.

When the mixture starts to dry, the material shrinks significantly, up-to one-seventh of its original volume, resulting in a considerably dense material that is water soluble and can be coated and painted.

The strength and hardness of the final composite is comparable to hard maple or ebony.

Ingredients of the composite:

- Water

- Hemp fibers (sourced from processed hemp paper and further refined)

- PH stabilizer

- Mineral pigments

It doesn't contain any binders, epoxy or glue.

Only Good News by Isola, DDW 2021

Location: Pennings Foundation, Eindhoven, NL

Photo by: Anwyn Howarth

Design: S Mate Olah

Production: Norbert Schmid – Drumparam & S Mate Olah

Material: Hempstone® sprayed on hemp ropes.

Between two plywood boards, a hemp net was suspended and multiple layers of Hempstone were sprayed onto its surface.

The net structure was chosen because it doesn’t have any sharp corners that could make the material crack while shrinking. It allows the material to cover the ropes all around so the material stays on the surface and shrinks more evenly.

The flexible net structure gives room for deformation showing the immense forces of the material while shrinking, allowing deformation and resulting in a dynamic appearance.

Hemp is a versatile ingredient for biomaterials and a fast-growing plant that is considered a CO2 sink due to its CO2 binding properties.

It contains one of the strongest natural fibres and can be used for manufacturing textile, cellulose plastics, paper, composites, cosmetics, food, medication, and more.

Template of the Hemp Chair. The silhouette is inspired by Armchair 42 by Alvar Aalto.

Building the framework for the hemp net structure

Hemp rope net in the making

Drilling holes along the silhouette of the chair.

ready to be sprayed with Hempstone, a mixture of water and finely grinded natural hemp fibers. (no epoxy or any other binders needed)

Small metal rods are used to reinforce the structure and make it more resistant to the strong forces of shrinking hemp composite.

Hempstone is sprayed from all possible directions onto the net structure by Norbert Schmid.

wet Hempstone surface

Hemp Chair after it is sprayed with Hempstone.

Smoothing and compressing the surface of the sprayed composite.

Smoothed Hempstone surface

Drying

Hemp Chair – varnished to make it waterproof

The chair was shaped by the shrinkage force of Hempstone.

This is especially visible around the top and bottom edge when compared to the original unsprayed net structure.

Hempstone is a biocomposite material that doesn’t require any binders and consists of water and hemp fibres.

The secret behind this material is the way it is processed: By grinding the hemp to a fine degree the surface area of the fibers are increased and when water is added intermolecular hydrogen bonds are formed between them.

This is the same reason why paper fibres stick together but the main difference is the strength of the bonds between the fibres.

The hemp is mixed with water in a 1 to 10 ratio and sprayed in multiple layers and dyed with mineral pigments.

When the mixture starts to dry, the material shrinks significantly, up-to one-seventh of its original volume, resulting in a considerably dense material that is water soluble and can be coated and painted.

The strength and hardness of the final composite is comparable to hard maple or ebony.

Ingredients of the composite:

- Water

- Hemp fibers (sourced from processed hemp paper and further refined)

- PH stabilizer

- Mineral pigments

It doesn't contain any binders, epoxy or glue.

Only Good News by Isola, DDW 2021

Location: Pennings Foundation, Eindhoven, NL

Photo by: Anwyn Howarth